The manufacturing practices, labour records, and supply chains of companies came under more scrutiny than ever this year, with global NGOs keeping up pressure on firms to eradicate slavery from their operations, cut greenhouse gas emissions and reduce environmental impact.

While campaigns by activists and industry watchdogs revealed that the private sector has a long way to go before their operations and supply chains are truly sustainable, there were also encouraging innovations from companies to tackle issues such as deforestation, electronics waste, and packaging waste.

Here are the top 5 manufacturing stories in 2016:

1. Spotlight on slavery

From fashion brands to mica producers, manufacturers from various sectors came under fire for using slave and child labour this year.

Activists around the world exposed the exploitation of Syrian refugees in Turkish factories that supply to brands such as Marks & Spencer and online store Asos, Burmese migrants in Thailand’s poultry farms, workers on tea plantations in South India as well as textile mills, and palm oil plantations in Indonesia and Malaysia.

Overall, about 46 million people live as slaves worldwide, according to the third annual Global Slavery Index released in June by Australian human rights group Walk Free Foundation. India and North Korea are among the worst offenders.

Researchers said that businesses should expect greater public scrutiny over slavery in their supply chains this year onwards, thanks to new laws that require them to report on efforts to eradicate forced labour, such as the United Kingdom’s Modern Slavery Act.

Campaigners also called on companies to make their supply chains more transparent. A new Transparency Index, launched in April by non-profit Ethical Consumer and campaigning organisation Fashion Revolution, ranks fashion companies on supply chain transparency, while global charity Oxfam in November unveiled a list which classifies clothing retailers as ‘Naughty’ or ‘Nice’ based on whether they disclose their factory lists and locations.

Companies and consumers wanting to check for slavery in clothing supply chains may soon have new tools to do so: US-based firm Applied DNA Sciences in November announced it is working on a way to use DNA analysis to trace the origin of fibres in clothes. Cotton grown in Uzbekistan, Turkmenistan and Tajikistan is likely harvested by slaves, according to the Walk Free Foundation.

2. Sustainable packaging revolution

Scientists around the world unveiled innovations that make packaging—one of the biggest sources of waste worldwide—more effective and sustainable.

In August, researchers from the US Department of Agriculture unveiled an edible form of packaging made from milk protein; they say the film is 500 times better at protecting food from oxygen than plastic wrapping, with the added benefit of being biodegradable and sustainable.

Meanwhile, scientists at Singapore’s A*Star—the national agency for research and development—in October showcased a new polymer plastic packaging that can help protect food from oxygen, heat, and light for longer, thereby reducing food waste.

These efforts will need to scale up fast, said experts. The Ellen MacArthur Foundation and World Economic Forum, in a February report, noted that at least 8 million tonnes of plastic end up in the ocean every year—that’s about one garbage truck worth of garbage tipped into the sea every minute.

If nothing is done to change how companies manufacture and design packaging, plastic pollution rates could increase to two trucks per minute by 2030, and four by 2050, warned the report. It called on companies to apply circular economy principles to the issue by creating secondary markets for plastic packaging and innovating packaging that is easier to recycle.

Global consumer goods firms also got onboard with the sustainable packaging revolution. American retail giant Walmart in October unveiled a Sustainable Packaging Playbook that it says will help achieve its zero waste goals, while PepsiCo said it would design 100 per cent of its packaging to be recyclable or recoverable by 2025.

3. Progress towards a circular electronics economy

Mobile phones have traditionally been regarded as too costly and difficult to recycle, because the quantity of minerals in a single smartphone is also not worth much. The cost of dismantling, transporting, and processing them to recycle also tends to outweigh the benefits.

As a result, smartphones often end up as electronic waste, and hundreds of tonnes of precious metals such as tungsten, silver, gold, and cobalt are squandered.

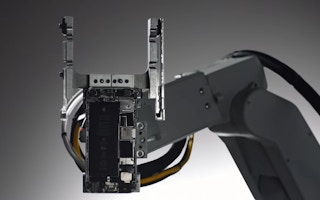

But this may soon change, thanks to a robot called Liam. Invented by tech giant Apple, the robot can take apart an iPhone in just 11 seconds, and is part of the company’s efforts to move towards a more circular economy.

The company already has two such robots—an industry first for disassembling electronics—installed in the US and Europe; according to reports, Apple hopes its competitors will copy the technology.

4. World’s first zero deforestation policy for rubber

French tire manufacturer Michelin in June adopted a zero-deforestation policy for its rubber sourcing, the first such global policy for rubber. The commodity has been identified as one of the leading causes of deforestation in Southeast Asia and Africa, and Michelin is the world’s largest buyer of natural rubber.

Environmental campaigners such as Greenpeace and World Wide Fund for Nature (WWF) welcomed the move, and urged other tire and care manufacturers, as well as vehicle fleet operators to commit to using ethically produced rubber and tires.

5. Environmental blind spots

Global consumer brands rely on a steady supply of commodities such as palm oil, soy and other crops, as well as a stable climate for their production processes; but they are failing to adequately consider their environmental impact, studies found.

In January, CDP, formerly known as the Carbon Disclosure Project, found that corporate giants like Dell, Unilever and Walmart had supply chains riddled with companies which did not respond to requests for climate action, let alone set their own targets for emission reductions.

This leaves companies with an incomplete picture of the climate risk they are exposed to, and hinders their ability to manage this threat.

In December, CDP also surveyed 187 firms and found that found that companies that rely on beef, palm oil, soy, and pulp and paper are underestimating how deforestation in their supply chains threatens their ability to fulfil their own promises to end forest destruction.

By failing to consider how deforestation in the supply chain is a business risk, companies could face severe disruptions to their own operations, higher raw material costs, and ultimately, revenue losses.

As Katie McCoy, head of forests, CDP, noted: “Supply chains are like rows of dominoes: if unsustainable commodities enter the top of a supply chain, the effects will cascade throughout.”

This story is part of our Year in Review series, which looks at the top stories that shaped the business and sustainability scene in each of our 12 categories.