Infrastructure provides all the vital services to keep an urban area functioning, from transport and energy to utilities and waste disposal. Sustainable or not, our need for infrastructure is growing.

To continue reading, subscribe to Eco‑Business.

There's something for everyone. We offer a range of subscription plans.

- Access our stories and receive our Insights Weekly newsletter with the free EB Member plan.

- Unlock unlimited access to our content and archive with EB Circle.

- Publish your content with EB Premium.

This is for two main reasons: we have a growing global population, which means a higher demand for infrastructure and, on top of that, a large proportion of this population is being born into or migrating into cities. Currently, over 50 per cent of the global population live in cities and that figure is set to rise to 60 per cent by 2030.

According to the Asian Development Bank, Asia-Pacific alone requires an investment of $1.7 trillion a year over the next decade in order to keep up with economic growth and tackle poverty and climate change. Investment in infrastructure projects across Indonesia, in particular, has risen rapidly to respond to an economy that is set to expand by 5.3 per cent this year and the next.

This will lead to the consumption of vast amounts of virgin materials and has the potential to further exacerbate climate change if unmanaged. And it is not just in Asia Pacific, other parts of the world are urbanising too. Surely we need some seriously strong incentives and regulation to make sure that we build sustainably?

A journey of learning but… how long have we got?

Policy and industry attitudes are changing, but is this change happening fast enough to mitigate the effects of climate change? In my opinion, public procurement strategies should be setting targets which are far more challenging to the construction industry, particularly on the environmental impact of the materials used and the finished asset.

But we are going to need a lot more than political will to mitigate pollution and improve efficiency in the construction industry. We will need further research and development into areas such as digitalisation, electromobility, virtual reality, 3D printing, new materials, the redesign of existing products, and the subsequent trialing of these innovations. This will require new types of collaboration and business models.

Sectors such as energy are already investing heavily in R&D, for example in battery storage, and consequently advancements in efficiency and decarbonisation. As this sector and others advance, the need for the construction industry to make changes becomes ever pressing. But in an industry that is so risk-averse, how can innovation and collaboration be promoted and invested in?

One movement that aims to support collaboration between researchers, key industry players, and environmental specialists is the Construction Climate Challenge initiative hosted by Volvo CE. These different groups come together to share knowledge, costs, risks – and ultimately the benefits – of working collaboratively to develop new ways to cut carbon in the construction and procurement industry. Presenting their experience demonstrating efficiency and associated cost savings helps advance new ways of working within the construction industry.

“

We need to redesign products, infrastructure and policy in an integrated way so that we maximise the benefits if we are to build a better tomorrow.

The benefit of going round in circles

The definition of sustainable development is the process of maintaining a balanced environment that meets life’s needs now and, in the future. The sustainable element of infrastructure is not just in the upfront design, construction methods and use of materials in the asset, but also its operation, maintenance, and disposal—this is the basis of a circular economy.

A circular economy is an economic system aimed at minimising waste and making the most of resources. So, when designing and building infrastructure the whole lifecycle needs to be considered. We can then focus far more holistically on how to make the asset more sustainable – be that design for deconstruction or complete recyclability.

And the value of understanding the life cycle of materials is being widely recognised by industry and policy. The European Union has estimated that by extracting maximum value and use of raw materials – through waste prevention, eco-design, and reuse – EU businesses could save €600 billion while reducing greenhouse gas emissions by up to 4 per cent.

We’re increasingly seeing more understanding of product responsibility and this has been reflected in a number of policies and product standards particularly in the EU. The EU’s Circular Economy Package’s (CEP) revised text states that improving the efficiency of resource use and ensuring that waste is valued as a resource can contribute to reducing the dependence on the import of raw materials and facilitate the transition to more sustainable material management and to a circular economy model.

Once we’ve identified all the steps in producing, using and decommissioning our infrastructure we have to go about making these steps not only sustainable but affordable. This will require investment to build capacity to execute these steps, which will, in turn, lead to the added benefits of upskilling the industry and creating jobs to support this new infrastructure.

Procurement strategies, also known as balanced scorecards, help identify the best possible design to maximise the social economic and environmental performance of a whole project, and this is absolutely key. But these strategies need to be more ambitious to further stimulate innovation.

Paving the way for sustainable infrastructure

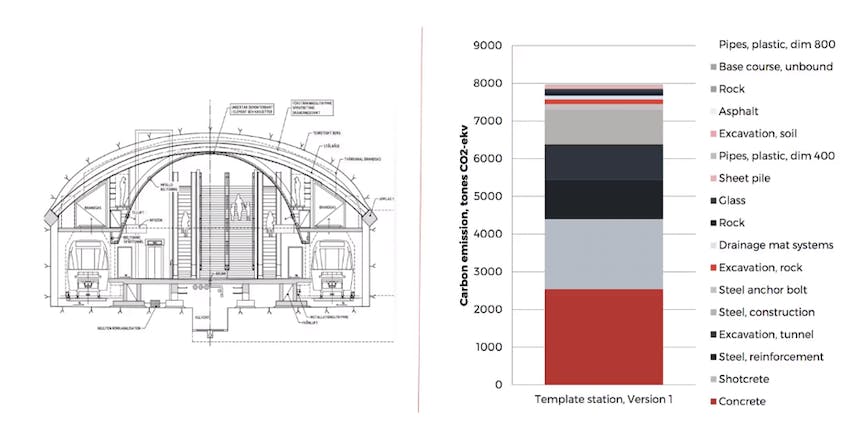

One project that has come a long way in this regard is the Stockholm Metro Extension project. The project comprises of 20km of new track and 11 new train stations. To aid the design process a template station was developed as a model for all the stations. To reduce the carbon footprint of the stations, the project team first calculated the cost and the carbon footprint for the template station (Figure 1). Concrete and steel were the main contributors to the carbon footprint.

Figure 1

They then identified measures for reducing material use and redesigning the station. The biggest carbon cuts came from the reduction of steel and the incorporation of recycled steel and other materials.

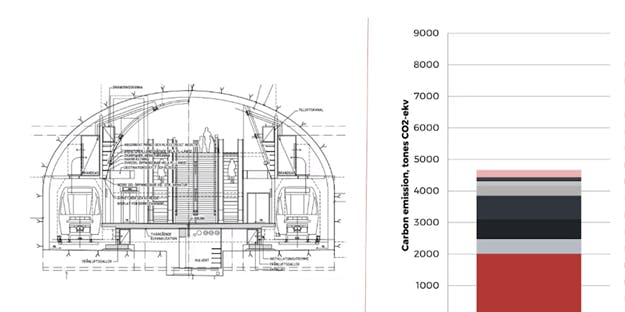

The final step was to follow up the results and make a new carbon calculation to reduce the carbon even further for the second version of the template station (Figure 2). By following this process, not only was carbon reduced by 40 per cent, but costs were reduced by as much as 30 per cent, as well as the physical amount of construction materials used.

Figure 2

There is a long way to go but one thing is clear, conventional construction methods and processes with existing materials are not the future. Ultimately, we need to redesign products, infrastructure and policy in an integrated way so that we maximise the benefits if we are to build a better tomorrow.

Dr. Paul Toyne is a non-executive director and independent advisor to business and government, specialising in the sustainable built environment.