This training is one of the few international classes that will be focused on applying Lean Six Sigma to environmental impacts.

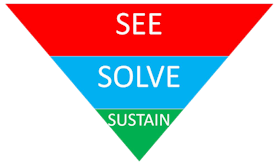

The 1-day class will cover the 3 step process (See, Solve and Sustain) for reducing environmental impacts with your clients, or within your own organization. This approach can work for any type of problem, but our examples and focus will be on the 5 types of environmental W.A.S.T.E. (Water, Air Emissions, Solid Waste, Toxins, and Energy).

We will cover an overview of each of the 3 steps, providing examples of how some of the tools or concepts apply.

After taking the course, you will feel confident in your ability to understand the See, Solve, Sustain framework, and determine what gaps you have in being able to follow this approach in your organization or with your customers or clients. You will not be an expert after just two days, but through practice and support from us, you will be able to make a huge impact on the environment.

This approach will work with companies and agencies at any phase of their environmental journey, whether they are just getting started, or already industry-recognized for their stewardship.

Within each step, we will cover many of the following concepts, tools or techniques

Step 1: SEE

- Overview of See, Solve and Sustain

- Motivation to improve

- Case Studies

- 5 lean principles

- 8 Forms of Waste

- Environmental wastes

- Identify your value stream

- Go and See

- Current, Ideal and Future State

- Problem Statements

- Process Management

- Clarify the problem

- Change Management

- New Tools (Green Impact Matrix, Green Systems Boundary Map, Eco Maps)

Step 2: SOLVE

- Process Mapping

- Data Collection Tools

- Personal Time

- Easy Improvements

- Simple experimentation & split testing

- Problem Solving Models (PDCA, 8-Step, DMAIC, A3)

- Event types (kaizen, projects, bursts)

- Kanban

- Supermarkets

- Theory of Constraints (TOC)

- Single piece flow

- 5S workplace organization

- Value Stream Mapping (VSM)

- Cellular flow

- Communications boards

- Root Cause Analysis Tools (5 Why’s, Fishbone, Pareto, Graphical Analysis)

- 3P (with biomimicry)

- Common vs Special Cause (Capability, Control charts and SPC)

- Risk Analysis (Brainstorming, Failure Modes and Effects Analysis)

- Measurement System Analysis (Gage R&R)

- Advanced statistical tools (ANOVA, Regression, DOE)

- Multi-voting

- Pilot projects

- Validation studies (statistical tests)

Step 3: SUSTAIN

- Empowering team

- Cost Savings

- Andon flags and lights

- Process and visual controls

- Report Out and Replicate

- Process Management Structure

- Daily continuous improvement

- Sustaining the culture of improvement

The training will be held in Portland State University.

Sponsor/exhibitor contact

Brion Hurley

[javascript protected email address]

Publish your content with EB Publishing

It's about who you reach. Get your news, events, jobs and thought leadership seen by those who matter to you.