Many of us think we know what electronic waste is because we wonder what to do with devices we no longer want or need.

It’s the old cellphone and its charger stuffed in the drawer.

It’s that old laptop, monitor or printer packed behind the door or in the basement.

It’s also all those things we throw out that are exported overseas, and picked over by people who are either desperate for work, despite the health and environmental risks, or at the forefront of a new green economy, depending on the narrative you hear.

But it is far more than all of that.

Waste arises ubiquitously, but unevenly, throughout the lives of electronics, not only when users discard their devices. No amount of post-consumer recycling can recoup the waste generated before consumers purchase their devices.

Waste from mining

Data on waste generation typically separates producer wastes, such as those from mining, and consumer wastes such as those from households. But there are problems with such division.

It makes the mistake of thinking producer waste and consumer waste are two separate things instead of flip sides of the same coin in industrial systems. It also makes the mistake of presuming consumers have much in the way of meaningful choice in what their electronics are made of.

Electronics contain a wide variety of materials. One important example is copper. The electronics industry is the second-largest consumer of copper. Only the building and construction sector uses more.

About 30 per cent of world copper consumption is satisfied from recycling copper scrap. The rest needs to be mined. A United States Geological Survey (USGS) study claims that for every kilogram of copper mined, at least 210 kilograms of mine waste arise.

The same study reports that one of the largest copper mines in the world, Chuquicamata in Chile, generates a daily average of more than 298,000 metric tons of mine waste.

At that rate, it only needs to operate for about 12 hours before it generates as much mine waste by weight as Chile does e-waste in a year. After a little over 48 days of operation, the Chuquicamata mine generates about the same amount of mine waste by weight as the total annual e-waste arising in China and the United States combined.

Waste from manufacturing

Manufacturing digital devices entails substantial tonnages of discards that, by weight, far exceed what consumers dispose of as e-waste. For example, in 2014, about 3.1 million metric tons of e-waste was collected from households in the European Union. Yet five times more waste, 16.2 million metric tons, arose from electronics manufacturing within the EU.

This means that even if all household e-waste collected in the EU is recycled, waste from manufacturing electronics in the same region far outstrips the scale of household e-waste.

Data from manufacturers of phones, laptops, desktops and tablets show that in most cases the CO₂ released over a device’s lifetime predominantly occurs during production, before consumers buy their devices.

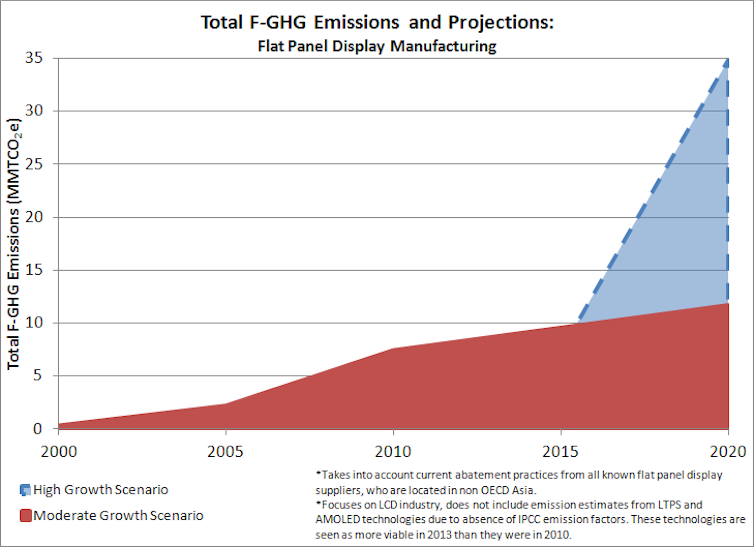

Similarly, the manufacture of flat panel displays, like those that go into televisions and computer monitors, releases fluorinated greenhouse gases (F-GHGs), some of the most powerful and persistent of the heat-trapping emissions.

Large volumes of other chemicals used in device manufacturing also don’t make it into the final device. The volume of these chemicals may be four times greater than what is included in the product itself.

Some of these chemicals are released into the environment, and make their way into workers’ bodies.

Waste from use

Once they’re in use, it can be tricky to measure the environmental impact of energy use by electronics. The electricity the device uses may be generated by coal, hydro or solar power plants. But it’s clear that the environmental impact of cyberspace is anything but “virtual.”

Minting a new bitcoin, for example, can produce seven to 12 tonnes of CO₂ per coin. Researchers estimate that electricity use for electronics in businesses and homes are responsible for about two per cent of total global greenhouse gas emissions. By 2040 those emissions could account for six to 14 per cent of total global greenhouse gas releases.

Fixing the e-waste issue

Post-consumer recycling of electronics will never be enough, we need to be able to repair — and upgrade — the devices we already have, if we are to slow our production of e-waste.

Innovative initiatives that facilitate reuse and repair while also finding ways to offset e-waste that arises do exist. More are needed.

“

No amount of post-consumer recycling can recoup the waste generated before consumers purchase their devices.

In the US, the Repair Association is doing the hard work of advocating for consumers to have the right to repair the devices they purchase by enshrining those rights into law. That said, an e-waste recycler in California now faces a 15-month prison sentence and a US$50,000 fine in his efforts to extend the lives of computers.

The automobile, food and pharmaceutical industries have to show their products meet certain safety standards before they are put on the market. Why not demand the same of the electronics industry?

![]() Requiring electronics manufacturers to make products that are materially safer, durable and repairable would be important steps in mitigating waste from electronics throughout their life cycle in ways that post-consumer recycling on its own will never achieve.

Requiring electronics manufacturers to make products that are materially safer, durable and repairable would be important steps in mitigating waste from electronics throughout their life cycle in ways that post-consumer recycling on its own will never achieve.

Josh Lepawsky is Associate Professor of Geography at Memorial University of Newfoundland. This article was originally published on The Conversation.