Singapore-based IIa Technologies on Tuesday, 17 March, opened the world’s largest diamond ‘greenhouse’ in the country, a state-of-the-art laboratory which makes diamonds that cost about 40 per cent less than natural mined diamonds, but with none of the environmental or ethical controversies that surround the precious stones.

Located in the city-state’s Tukang Innovation Drive industrial area, the new 200,000-square-foot facility houses about 200 diamond greenhouse machines that use a revolutionary method known as Microwave Plasma Chemical Vapour Deposition (MPCVD) to grow Type IIa diamonds, the purest diamond that can be found underground.

The facility aims to fill the widening gap between global demand for diamonds and available supply from mines, as well as open up new possibilities for the use of diamonds in high-technology applications in precision engineering, optics, healthcare, and electronics manufacturing, among others.

Vishal Mehta, chief executive officer of IIa Technologies, predicted that the supply of grown diamonds will be in high demand among jewellers and technology businesses, thanks to growing demand from industries and increasingly affluent consumers in countries such as India and China.

Bridging the supply gap sustainably

Global diamond supply has been constantly declining in the past decade, and several key mines have passed their peak production levels. Global consultancy Frost and Sullivan in a recent report found that the global supply of mined rough diamonds could fall from 134 million carats in 2014 to 14 million carats by 2050.

Demand is expected to rise to 292 million carats, leading to a potential supply gap of 278 million carats by 2050.

Lab-grown diamonds could have a major role in addressing this shortage. Frost and Sullivan predicts that grown diamond production will exceed 200 million carats by 2050, with about 55 million carats being used as gems, and 150 million carats being used in hi-tech applications.

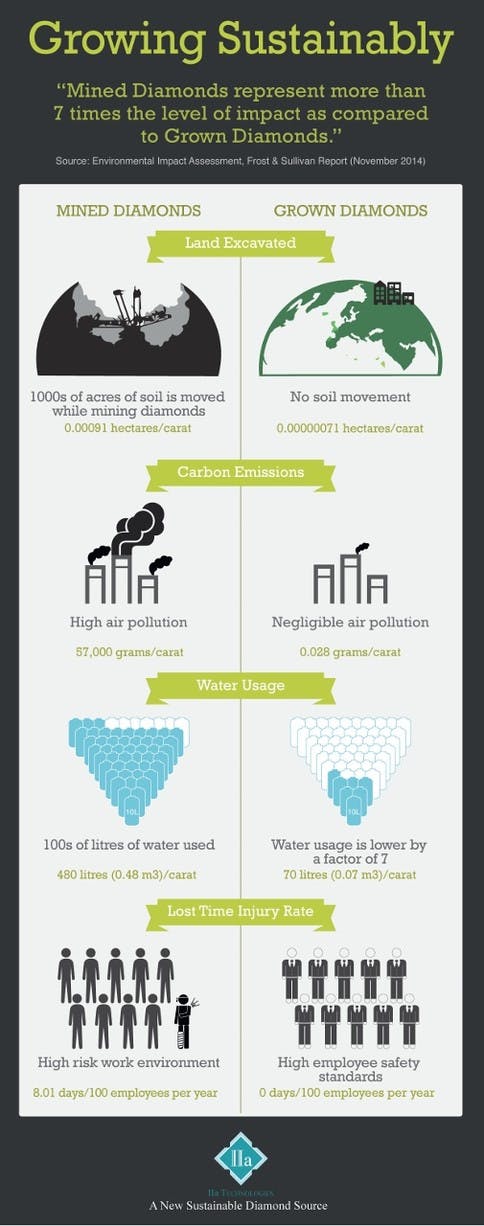

A comparison of the environmental and social impact of grown and natural diamonds. Image: IIa Technologies

Grown diamonds also have less than one-seventh of the impact of mined diamonds when factors such as carbon emissions, energy usage, land disturbance, and occupational hazards are taken into account, Frost and Sullivan found.

The human rights controversies surrounding mined diamonds, such as the use of ‘blood diamonds’ to fund conflicts, poor or violent working conditions for miners and the use of child labour in mines also do not apply to diamonds that are grown in laboratories, says IIa Technologies.

“We bring a sustainable source of rough diamonds to both traditional and next generation applications,” said Mehta, who also announced the launch of a new Centre of Excellence which will conduct research on how diamonds can be used in industry, and on improving the company’s diamond production method MPCVD.

The method, developed by Indian professor Devi Shanker Misra, who is now IIa Technologies’ chief technical officer, involves placing diamond ‘seeds’ - thin, square diamond wafers that are up to 11 millimeters wide - in a chamber which is filled with hydrogen and methane gases.

Microwave energy ignites the hydrogen into a high-energy ball of plasma, which hovers above the seed and heats up the methane, which is made up of hydrogen and carbon. The heat causes the carbon atoms in the methane to ‘rain’ onto the seed and form a diamond crystal.

This process takes between 10 and 12 weeks, at the end of which a rough grown diamond is sent for cutting and polishing.

IIa Technologies produced about 300,000 carats of grown diamonds last year, says Mehta.

Changing jewellery and hi-tech industries

These stones go through an extensive supply chain passing through India, China, and other countries before ending up in luxury markets or industrial products.

“

Creating a diamond resource within Singapore truly showcases what the country stands for - progressive technology, innovation, and business resilience.

Vishal Mehta, chief executive, IIa Technologies

They are sold to consumers via the New York-based Pure Grown Diamonds company, which is also owned by IIa Technologies’ parent company, IIa Holdings Group. Pure Grown Diamonds has a large retail presence in the United States, and also conducts worldwide sales through its online store.

Mehta shared that while that the company has not made an extensive foray into consumer markets in Asia, he was optimistic that the diamonds would be popular in the region.

Philippines-based jewellers Golcondia Cultured Diamonds have been selling IIa Technologies’ grown diamonds in Manila since last year, in what managing director Thomas Florencio says is the world’s first exclusive showroom for cultured diamonds.

Daniela Fenix San Agustin, managing director, Golcondia Cultured Diamonds, told Eco-Business that consumers are not yet aware of the existence of grown diamonds. “Once consumers understand that they are real diamonds but grown differently, they see it as a good sustainable option,” she said.

IIa Technologies is also working with partners from technology companies and research institutes to develop new uses for diamonds in hi-tech industries at their new Centre of Excellence.

_popup.jpg?auto=format&dpr=2&fit=max&ixlib=django-1.2.0&q=45&w=280)

The MPCVD process in action at the IIa Technologies laboratory. Image: IIa Technologies

These could include creating diamonds with different physical or chemical properties - such as electrical conductivity, clarity, or ability to transmit infrared light - for customers, and building machines that can make diamonds to these specifications.

Singapore’s deputy prime minister and minister for finance, Mr Tharman Shanmugaratnam, who inaugurated Tuesday’s launch of the facility, said that he expected the centre to generate new applications for diamonds by working with industry and research partners.

“We look forward to seeing IIa spinning off new innovative applications and collaboration through its co-creation Centre,” he said, referring to the Centre of Excellence.

Shanmugaratnam added that IIa Technologies’ facility was an example of Singapore’s precision engineering industry transforming towards technologically advanced and value-added manufacturing, which was made possible by research and development and specialised skills.

Such niche specialisations “create opportunities for Singaporeans to develop high skills,” he said.

Singapore shines bright for grown diamonds

In turn, Singapore had also played a key role in the company’s success, said Mehta, who told Eco-Business that despite the family’s roots in India, the country’s unstable power system would have made it difficult to run the sensitive electronic equipment round the clock in India.

“A stable work environment, world class infrastructure infrastructure, and a highly skilled talent pool have allowed IIa Technologies to focus on its development process,” he said.

The company was incorporated in Singapore in 2005, and spent its first six years developing the MPCVD technology at a facility in Singapore’s Woodlands neighbourhood with research partners such as the Nanyang Technological University (NTU), the Agency for Science, Technology and Research (A*STAR), and Republic Polytechnic, among others.

The decision to expand the company’s operations came about in 2012, which spurred the move to the new facility. The company has invested a total of US$110 million in its facility and operations today.

“We also realised that if we were successful, an environment that respected intellectual property (IP) was important,” said Mehta, adding that strong government support from the Singapore Economic Development Board and other government agencies, Singapore’s focus on technology research and development, and skilled workers were also important pull factors.

“IIa Technologies could not have wished for a better home,” added Mehta, who went on to launch IIa Technologies’ ‘Cultured in Singapore’ brand mark. The logo, which will clearly indicate that all diamonds sold by the company were made in Singapore, will also “proudly position Singapore as a grown diamond resource for the world,” said the company.

“Creating a diamond resource within Singapore truly showcases what the country stands for - progressive technology, innovation, and business resilience,” said Mehta.

Edited by Jessica Cheam and Stanley Tang